Why You Should Always Prototype Your Product

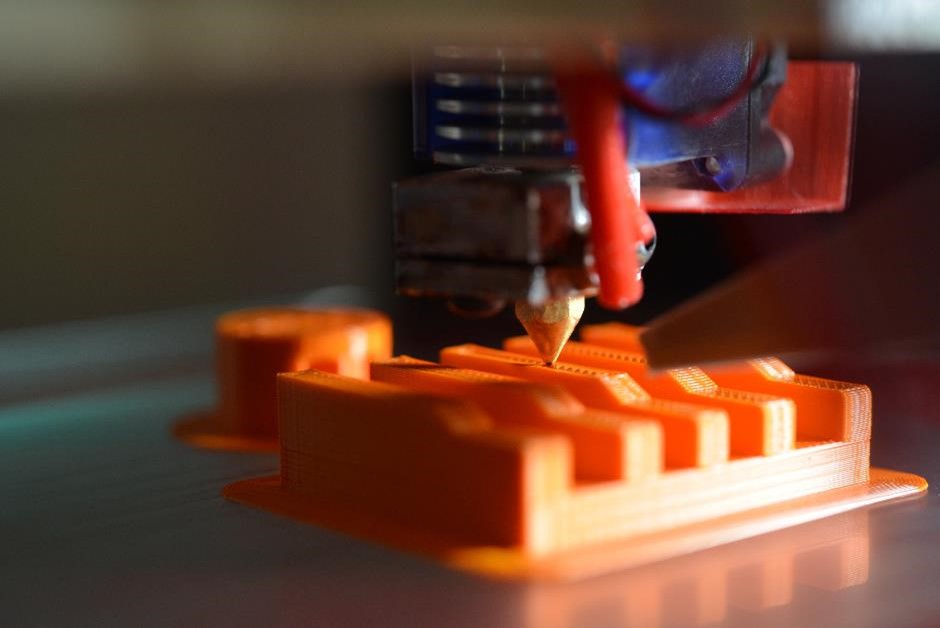

One of the key services we offer at Cornelius Creative is rapid prototyping using our in-house 3D printers and prototyping partners. It’s a fast, cost-effective way to bring product ideas to life – and it’s something we strongly recommend to every client.

Recently, a client asked us:

“Do I really need to prototype my product? Can’t I just go straight into production?”

It’s a fair question. But the reality is, skipping the prototyping stage can lead to costly mistakes. Prototyping isn’t just an optional extra – it’s a critical step that can save you time, money, and a lot of stress in the long run.

What is a Prototype?

A prototype is a physical 3D model of your product (or component). It shows how the final design will look and feel, and in many cases, how it will function.

Prototypes can range from basic mock-ups made from cardboard or foam, to professionally printed 3D models using plastics, metals, wood, or fabric. At Cornelius Creative, we use high-quality 3D printing to produce accurate and robust prototypes using materials best suited to your product. Depending on our client’s requirement, we will either use our suite of in-house printers or outsource to our professional printing partner.

Why Prototyping Matters

Our Managing Director, Simon, shared a video on this topic:

In short, there are three key reasons why prototyping is essential:

1. Identify Design Issues Early

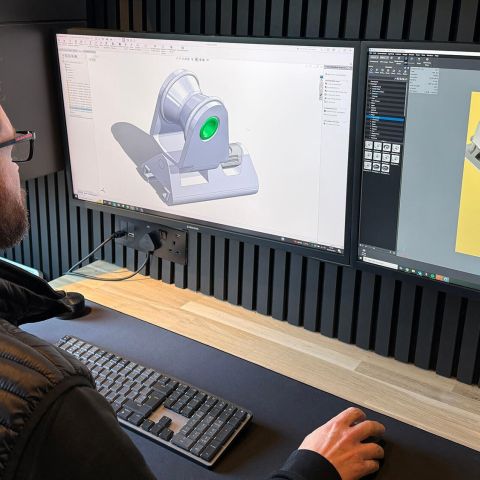

3D CAD models and photorealistic renders give a good indication of your product’s appearance, but they’re no substitute for a physical model.

A prototype lets you hold the product, examine it from every angle, and spot design flaws you might otherwise miss.

Catching these issues before production means you can change the design before investing in expensive tooling or manufacturing – saving you both time and money.

2. Test Functionality and Fit

A prototype isn’t just about appearance – it’s also about performance.

Does it feel right in the hand? Do parts fit together as expected? Is it durable under normal use?

Testing these elements during the prototyping stage is far more cost-effective than finding problems after production has started.

3. Gather Feedback from Users and Stakeholders

A working prototype allows you to gather valuable feedback from end users, investors, and internal stakeholders.

It’s a powerful tool for validating your idea – and making refinements before you fully commit.

Having a tangible prototype also builds credibility with investors and board members, showing that you’ve taken the product beyond just an idea.

How to Make a Prototype

There are two main routes:

✔ DIY Prototypes

If you’re handy and want to visualise your idea quickly, a simple model made from cardboard, foam, or other basic materials can give you a rough sense of the product. It’s a good starting point for very early-stage ideas.

✔ Professional 3D Prototypes

For meaningful testing and accurate validation, you’ll need a professionally made prototype. That’s where we come in.

We’ve been 3D printing since 2020 and it’s played a vital role in all of our product development projects since. Our printers produce detailed, functional prototypes that help our clients move confidently toward production.

Ready to Bring Your Idea to Life?

If you’re developing a new product and want to avoid costly mistakes, prototyping is the smart choice. Whether you need a simple model or a fully functional prototype, we’re here to help.

👉 Get in touch today to discuss your project or ask us any questions about 3D printing and product prototyping. We’d love to help turn your concept into reality.

Hungry for more?

Recent Posts

What are the Differences Between Traditional Photography and CGI?

Introducing Breakdown Buddy: A New Era of Roadside Safety

Using Customer Pain Points to Drive Product Innovation

The Rise of Fractional Work, and How It Could Transform Your Company

SolidWorks: The Secret to our Product Design Success

How to Patent an Idea in the UK

SBS Event 2025: Our Exciting Key Takeaways from Birmingham

Why We Changed Our Company Values

The Power of Visuals: How Computer-Generated Images Drive Product Sales