Unlocking the Potential of 3D Printed Prototypes: Why Collaborating with a 3D Printing Company Matters

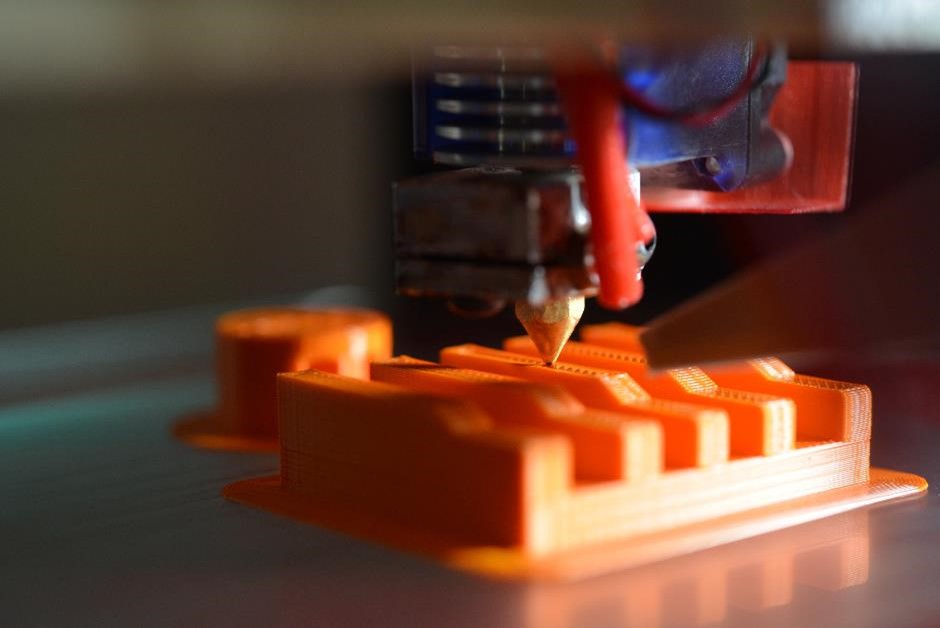

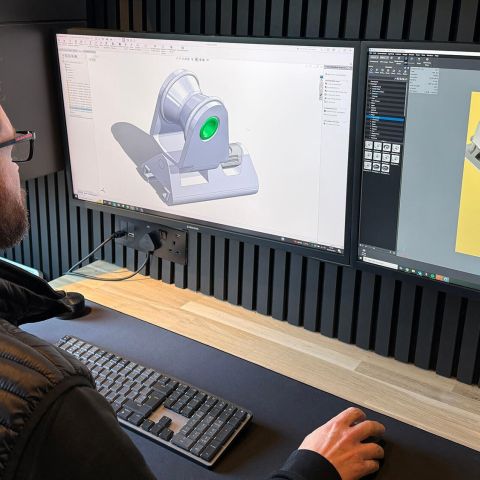

Bringing a new product to market can be exciting, but also complex, of course. One of the most critical stages in the product development process is prototyping: turning your design from a CAD file or sketch into something real, tangible, and able to be tested.

Today, businesses across various industries are increasingly turning to a 3D printing company to produce their prototypes. Why? Because 3D printing has revolutionised the way we approach design testing and product development – delivering speed, cost efficiency, and flexibility that traditional methods can’t compete with.

Here’s a look at the key benefits of creating a 3D printed prototype and why it should be an essential step in your next product development project.

1. Rapid Prototyping Speeds Up Time to Market

Before 3D printing became mainstream, producing a prototype was a slow and often expensive process. Traditional methods, like CNC machining or injection moulding, could take weeks or even months to deliver a working model. Each design revision meant further delays and more cost.

By contrast, a 3D printing company can produce a prototype within hours or days, depending on the complexity of the design. Designers and engineers can test, refine, and reprint their models in quick succession, dramatically reducing development time and accelerating the journey from concept to production-ready product.

This speed enables businesses to be more agile, responding faster to customer feedback, testing new concepts quickly, and beating competitors to market.

2. Cost-Effective Product Development

Traditional prototyping methods often require expensive tooling, specialised machinery, and skilled labour to operate. For small businesses or start-ups, these costs can be a major barrier.

Working with a 3D printing company is far more cost-effective. 3D printers use an additive manufacturing process, building objects layer by layer from digital files. This method reduces the need for tooling and minimises material waste, significantly lowering overall costs.

Because changes can be made directly to the CAD file and reprinted without starting from scratch, it’s also a cost-efficient way to refine a design iteratively.

3. Less Waste, More Sustainability

Sustainability is an increasingly important consideration in product design and development. Traditional subtractive manufacturing processes often result in significant material waste, as parts are carved from larger blocks of material.

With 3D printing, waste is greatly reduced. Only the exact amount of material required to produce the object is used, which not only lowers material costs but also supports more sustainable practices – something that consumers and stakeholders are increasingly prioritising.

4. Enhanced Design Flexibility and Customisation

Working with a 3D printing company opens the door to a level of design freedom not possible with traditional manufacturing. Complex geometries, intricate detailing, and lightweight structures can all be created with precision – without increasing costs or lead times.

This is particularly useful during early-stage development, when designers need to explore multiple versions of a concept or test different configurations. With 3D printing, customisation is quick and easy, supporting a more creative and experimental design process.

5. A Competitive Advantage in Sales and Investment

Having a high-quality, tangible prototype to show clients, investors, or stakeholders can be a game-changer.

It’s far easier to build trust and excitement when someone can hold your product in their hands, rather than view it on a screen. Whether you’re looking for investor funding, pitching a new product line, or securing pre-orders, a physical prototype adds professionalism and credibility to your pitch.

Prototypes also help uncover design flaws early, reducing the risk of costly mistakes once manufacturing begins. This proactive approach leads to better products, and a smoother path to commercial success.

Partner with a 3D Printing Company You Can Trust

At Cornelius Creative, we work closely with our clients to bring their ideas to life – fast. As part of our product development service, we offer in-house 3D printed prototypes, allowing for quick turnaround and high-quality results. And for more advanced or specialist prototypes, we also collaborate with our trusted 3D printing partners.

Whether you’re refining an idea or getting ready for manufacturing, we can help you create a prototype that delivers impact and moves your project forward.

Ready to Push ‘Print’?

If you’re looking for a reliable 3D printing company to support your next product prototype, we’d love to help. Our expert team can guide you through the process – from concept to printed prototype – with speed, efficiency, and creative insight.

📞 Call us on 01474 368654 or 📧 email us today to discuss your project.

Hungry for more?

Recent Posts

What are the Differences Between Traditional Photography and CGI?

Introducing Breakdown Buddy: A New Era of Roadside Safety

Using Customer Pain Points to Drive Product Innovation

The Rise of Fractional Work, and How It Could Transform Your Company

SolidWorks: The Secret to our Product Design Success

How to Patent an Idea in the UK

SBS Event 2025: Our Exciting Key Takeaways from Birmingham

Why We Changed Our Company Values

The Power of Visuals: How Computer-Generated Images Drive Product Sales