Using Customer Pain Points to Drive Product Innovation

In the world of product development, innovation doesn’t start with materials, manufacturing, or even design – it starts with people. But the most successful ideas rarely come from a boardroom brainstorm – they come from your customers, and more specifically, their problems.

Understanding real-world customer pain points is one of the most effective ways to develop products that solve genuine problems and deliver meaningful value. When you focus on the frustrations, inefficiencies, or unmet needs your customers face, you gain a direct line to designing products that truly make a difference.

What Are Customer Pain Points?

Customer pain points are the frustrations, inefficiencies, or challenges that users face when interacting with a product. When we think about product design and development, these issues often relate to usability, durability, ergonomics, size, weight, or material choices.

For example:

- A kitchen appliance might be too heavy to lift comfortably

- A hand tool could cause fatigue during extended use.

- Packaging might be difficult to open.

These issues, though seemingly small, are daily frustrations that customers often accept simply because they don’t see a better option. But these little problems can result in negative reviews, reduced customer satisfaction, and even returns or refunds, impacting the company’s reputation and sales.

So, for product designers, these pain points signal opportunities for improvement.

Why Pain Points Should Drive Product Innovation

Designing products based on customer pain points ensures that innovations are grounded in real need, not just assumptions. This leads to better user experiences, stronger market fit, and ultimately, greater commercial success.

Many leading product design and development firms in the UK use pain point analysis as a core part of their design process. By addressing these issues early in development, companies can reduce costly redesigns and create more competitive products.

How to Identify Customer Pain Points

This is where market research becomes essential. Rather than relying solely on surveys or broad demographic data, product design and development teams are increasingly turning to direct customer observation, interviews, and user testing. Watching how people use a product in real life often reveals subtle inefficiencies that customers may not even articulate. These insights are gold when it comes to innovation.

Here are some methods for discovering user pain points in product development:

1. Customer Interviews

Talking directly to your customers can reveal challenges that aren’t always captured in surveys. Ask open-ended questions about how they use the product, what frustrates them, and what they wish was different.

2. Observation and Field Research

Watching customers use your product, or even a competitor’s, can expose hidden issues, such as awkward handling, setup confusion, or storage problems.

3. Review and Support Channel Analysis

Online reviews and customer service logs are gold mines for pain point discovery. Look for repeated complaints, suggestions, or negative feedback patterns.

The key is to treat complaints not as criticisms, but as clues. Every customer frustration is an opportunity to create something better. When you hear recurring issues, for example, “It’s too hard to clean,” “It doesn’t fit in my cupboard,” or “It always breaks after a few months”, you’re receiving direct feedback on where your product can differentiate itself.

Design teams can also benefit from speaking with customer service teams and retail partners to identify patterns and collate research on which pain points are worth addressing in next generation products.

4. Prototype Testing

Put early prototypes in users’ hands and observe their behaviour. Where do they struggle? What seems unintuitive? This user testing phase is critical before committing to full-scale production.

Real-World Example: Innovation Through Frustration

One of our clients, Barton Marine, received customer feedback from dinghy racers and small cruiser sailors that identified a consistent issue in the market for small furlers (which are used to take in/out sails).

The feedback was that furlers were often low-end quality and compromised on performance, with many using serviceable bearings, which can fail prematurely in harsh marine conditions. The result was that it not only impacted reliability but also posed a serious risk of failure while at sea.

Additionally, most furlers on the market were not optimised for continuous-line systems (a single loop of rope) without removable parts – parts that can be easily dropped and lost overboard. The small-diameter drums commonly used also make them prone to rope slippage, reducing control and safety during use.

Our Solution: The HBT1 Furler

To address these challenges, we developed the HBT1 Furler – a compact, high-performance solution engineered specifically for the demands of dinghy and small cruiser sailing.

Here’s how it redefines expectations:

- Hybrid Bearing Technology:

The HBT1 features a hybrid bearing system that delivers smooth, reliable performance even under high loads. By eliminating traditional ball-raced bearings and minimising moving parts, we created a low-maintenance system that thrives in harsh marine environments. - Tri-Rotor Furling Wheel:

Our unique tri-rotor design dramatically improves rope grip and control. As the rope turns the rotor, each of the three blades bites into the rope, pulling it deeper into the grip channels to virtually eliminate slippage. - Tool-Free, Fixed Fairlead Design:

Rope insertion is quick and effortless – no tools required. The fixed fairlead is permanently integrated into the body, and its innovative geometry aligns perfectly with the rotor’s cutouts, ensuring a clean and secure rope path without the need for removable parts. - Compact and Lightweight:

By reducing component count and switching to a hybrid bearing system, we’ve minimised both weight and overall height. The result is a furler that is not only easier to handle, but also better suited to space-constrained rigs.

With the HBT1 Furler, we’ve set a new standard in the small furler market and overcome those customer pain points to combine durability, performance, and sailor-friendly design in one sleek, efficient package.

Final Thoughts: Turning Pain Into Progress

Using customer pain points to drive product innovation is not only smart – it’s essential. It grounds your design process in real-world needs and sets the stage for creating products that resonate with your target audience. By listening closely, observing carefully, and solving issues, businesses can create products that not only function well but also delight their users.

But identifying pain points is just the beginning – solving them creatively is what drives innovation. Whatever you’re designing – a tool, appliance, packaging system, or medical device – the most effective innovations arise from solving real problems.

To create products that stand out, you need to start by asking: What frustrates my customers? By using customer pain points as a guide, you ensure your product isn’t just new – it’s necessary.

Next steps

Looking to create your next product and solve your customers’ pain points? Our design team can execute the entire process, from market research to identify the pain points, through to design, engineering, prototyping and production. Speak to our team today and let’s get your next project underway.

Hungry for more?

Recent Posts

What are the Differences Between Traditional Photography and CGI?

Introducing Breakdown Buddy: A New Era of Roadside Safety

Using Customer Pain Points to Drive Product Innovation

The Rise of Fractional Work, and How It Could Transform Your Company

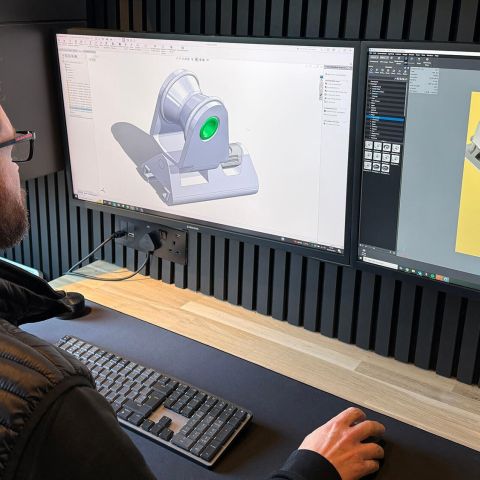

SolidWorks: The Secret to our Product Design Success

How to Patent an Idea in the UK

SBS Event 2025: Our Exciting Key Takeaways from Birmingham

Why We Changed Our Company Values

The Power of Visuals: How Computer-Generated Images Drive Product Sales