Developing a New Product: Expectations vs. Reality

It’s the start of a new year; the time when we typically set new challenges for ourselves. Businesses, start-ups and entrepreneurs tend to set goals for the year, and some of these goals may be related to new product development.

Creating a new product can be one of the most exciting and rewarding challenges in business. It’s the moment when ideas take shape, innovation meets market need, and something truly unique comes into existence. However, while the process often comprises an atmosphere of excitement and innovation, the reality of product development is far more complex and filled with unexpected hurdles.

In this blog post, we’ll explore the gap between the expectations and the reality of developing a new product. Whether you’re a startup founder, a product manager, or someone interested in the product development journey, understanding these contrasts can help you navigate the process with greater clarity and preparedness.

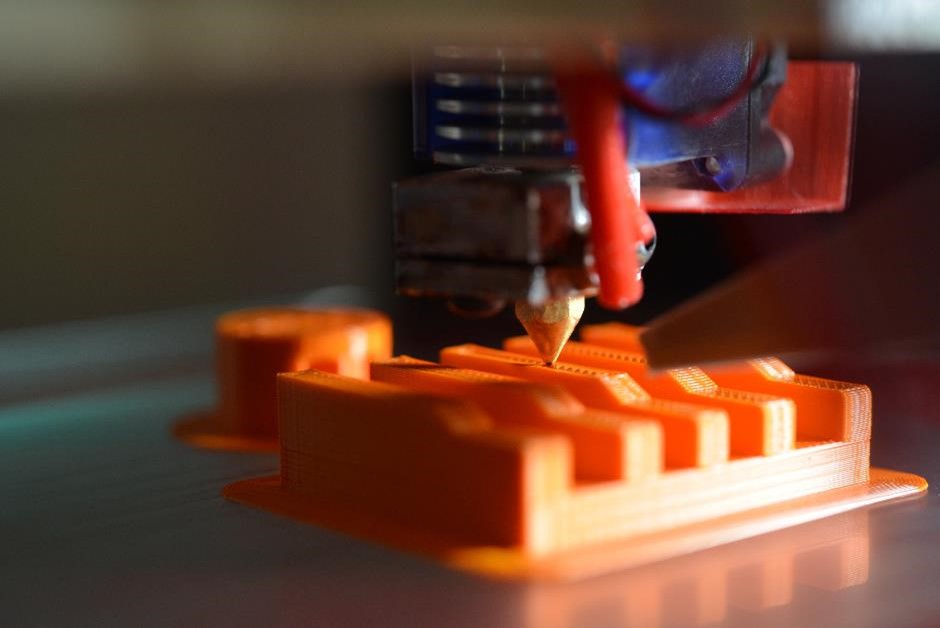

Expectation 1: The Idea Will Come Easily

Reality: Innovation is often a messy process.

When brainstorming a new product, we tend to imagine that the perfect idea will just click into place. Perhaps you envision yourself having a lightbulb moment or feeling a sudden burst of inspiration that leads to a flawless product concept.

In reality, developing a new product often begins with days (if not weeks, months or even years!) of research, iteration, and testing. The initial idea might be vague or incomplete, and it may need to be refined multiple times before it starts to resemble a viable product ready for the market. The creative process is rarely linear, and sometimes, the best ideas come from feedback, setbacks, or looking at the problem from different angles.

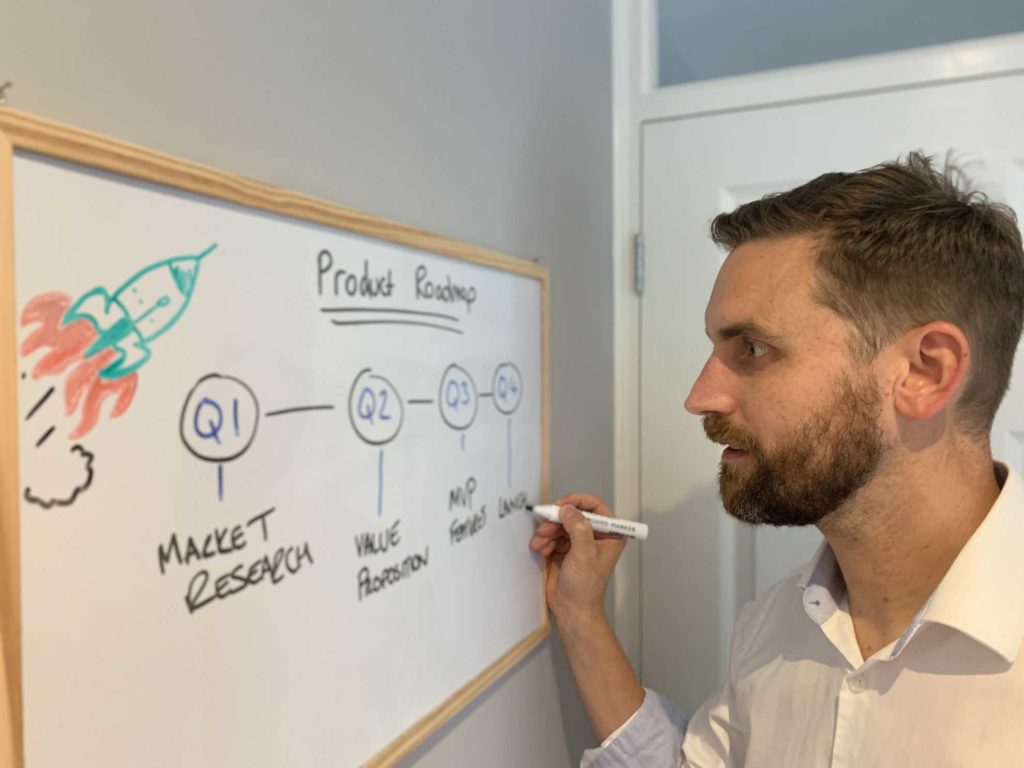

Expectation 2: The Development Timeline Will Be Predictable

Reality: Timelines almost always stretch.

You’ve created a product plan with clear deadlines, and everything seems set for a smooth rollout. But, as any product developer will tell you, timelines rarely hold up as expected. Delays can occur for numerous reasons – technical challenges, changes in market demand, unexpected customer feedback, or even the complexity of sourcing materials.

Moreover, each phase of product development typically takes longer than anticipated. From the design phase to prototyping, testing, and market validation, there will be setbacks and revisions. While some parts of the process can be managed more effectively, it’s important to be prepared for unexpected obstacles and build in contingency time to avoid frustration.

Expectation 3: Development Will Be a Collaborative, Unified Effort

Reality: Collaboration can sometimes be more challenging than anticipated.

The expectation: teams work together seamlessly, everyone is aligned, and there’s an easy flow of ideas. The reality? Product development often requires balancing a multitude of perspectives, from engineers and designers to marketers and business stakeholders. Everyone has their own priorities, and aligning all these views can lead to disagreements, delays, and confusion.

Additionally, cross-functional collaboration involves significant communication efforts. Teams need to maintain constant dialogue to ensure that everyone is on the same page. Miscommunication can lead to costly mistakes and coordinating schedules for everyone involved can be tricky.

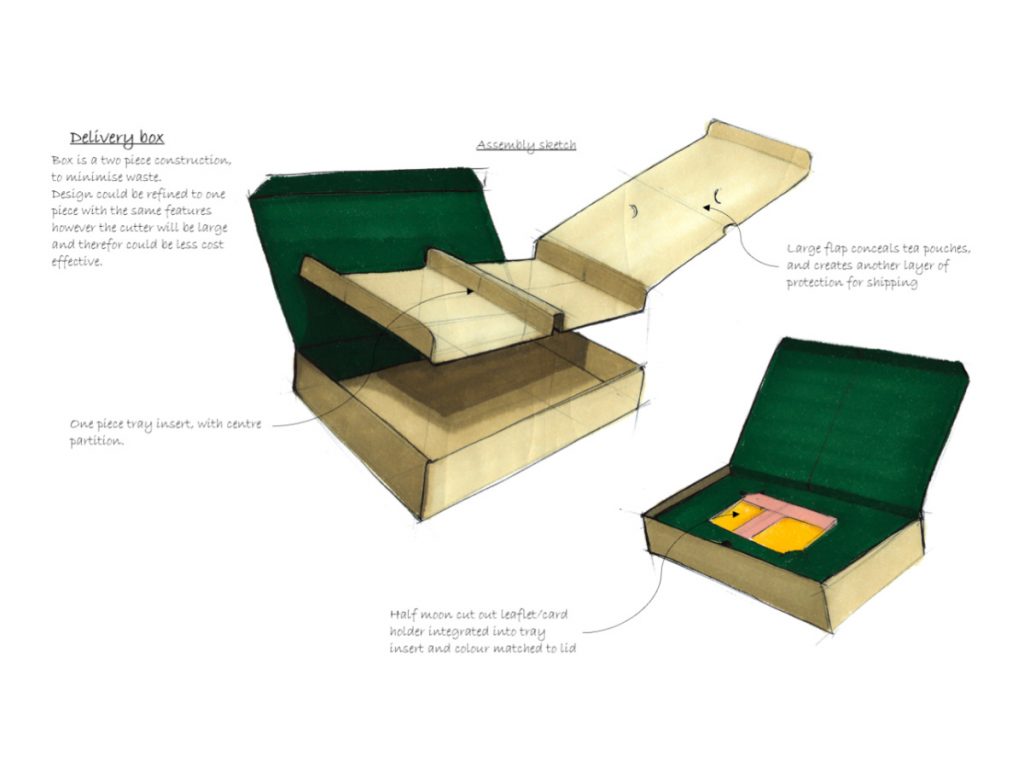

Expectation 4: Product Testing Will Be Smooth

Reality: Testing often uncovers a lot more than you expect.

Product testing is meant to be a phase of refinement, where you uncover and address issues before launch. While this phase is crucial to creating a high-quality product, it’s not uncommon for it to reveal far more problems than anticipated.

No matter how many prototypes you’ve built, the product may still face unexpected usability challenges. Design flaws sometimes often surface only when real users interact with the product. Testing isn’t just about fixing issues; it’s about rethinking assumptions, revisiting features, and sometimes going back to the drawing board entirely. The process can be frustrating, but it’s also the key to refining the product to ensure that it meets user needs and expectations.

Expectation 5: The Product Will Be a Hit Upon Launch

Reality: Gaining traction takes time.

There’s always hope that your product will immediately succeed once it hits the market. However, even the best products often require time to gain traction and attract a loyal customer base. Market conditions, customer education, and competition can impact a product’s success, even if it’s well-designed and solves a real problem.

For most products, the road to success involves careful marketing strategies, potentially improvements based on feedback, and even a bit of luck. You’ll likely face challenges post-launch, such as tweaking the product, revising messaging, or adjusting to user feedback. It’s rare for a product to hit the market and immediately find its perfect audience without a period of growth and adjustment.

Expectation 6: Financial Success Is Guaranteed

Reality: Financial success isn’t immediate or assured.

Developing a new product involves significant investment – both in terms of time and money. From development costs to marketing expenses, the resources required to bring a product to market are substantial. While the potential for financial success can be high, the reality is that product development comes with risks, and there are no guarantees that the product will turn a profit immediately.

In fact, many companies face financial pressure in the early stages, especially if the product takes longer to gain traction or if additional iterations are needed. Product success often requires a long-term vision, a willingness to pivot when necessary, and a constant focus on the evolving needs of your customers.

Key Takeaways

Developing a new product is as challenging as it is exciting. While there will certainly be moments of triumph and inspiration, you will also face obstacles that challenge your expectations and require flexibility, creativity, and perseverance. Embrace the unpredictability of the journey, stay agile, and be prepared to learn from both failures and successes.

By understanding the reality of product development, you can better manage expectations, anticipate challenges, and ultimately create a product that is well-aligned with the needs of your market. After all, the difference between a successful product and one that falls flat often lies in how well you adapt to the unexpected twists and turns along the way.

If you’ve reached the end of this blog post still determined to develop your next product, we have great news! We’re product development specialists, and we’ve gained a huge wealth of experience along the way. There aren’t many obstacles we haven’t faced, and we’re equipped to deal with them all. If you’d like to discuss next steps, book a call with our team today.